Embark on a journey through the heart of quality control and process improvement, where the notions of central tendency and inferential statistics weave a tale of understanding and advancement in the manufacturing landscape.

Embracing the Center: Central Tendency in Quality Control

Before we delve into the intricacies of inferential statistics, let’s explore the heartbeat of data analysis – central tendency. Imagine it as the gravitational force that pulls data towards its center, providing a sense of where the majority of values lie.

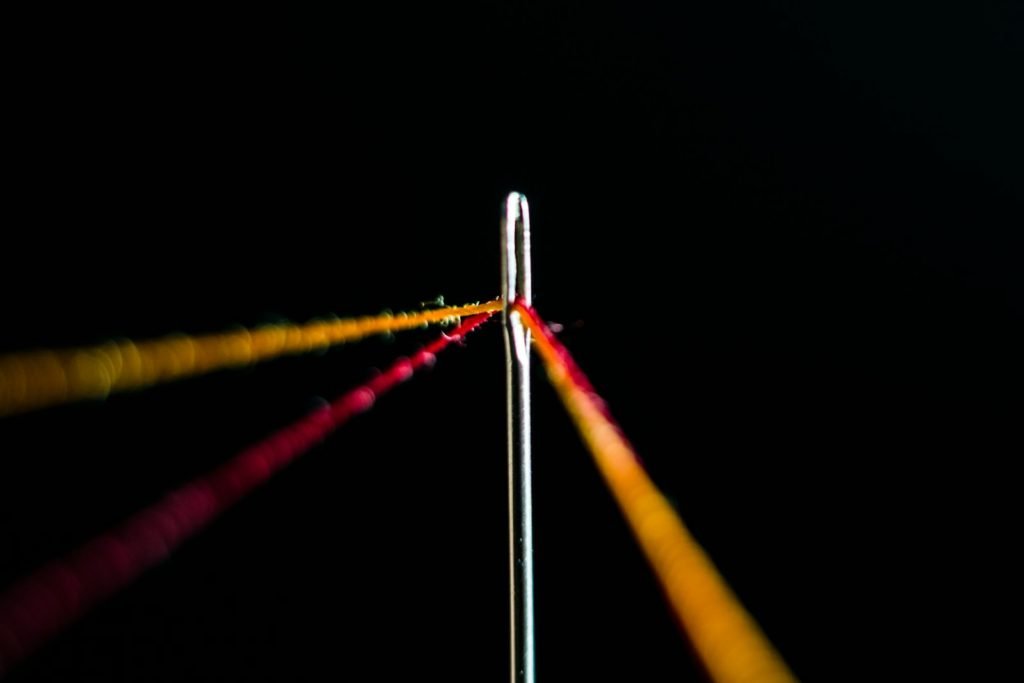

The Compass of Averages: Navigating the Middle Ground

Averages, like the steady needle of a compass, guide us through the middle ground of data. In quality control, the mean (average) is a common measure of central tendency, representing the sum of all values divided by the number of observations.

Understanding the mean helps manufacturers identify the typical value within a dataset. For instance, if measuring the dimensions of products, the mean provides a sense of the average size, serving as a reference point for quality assessment.

The Meditative Median: Seeking the Middle Path

Picture the median as a meditative monk, situated in the middle of a sorted dataset. Unlike the mean, the median is not influenced by extreme values. It’s the middlemost value that separates the higher half from the lower half.

In quality control, the median is a robust measure of central tendency, especially in the presence of outliers. If the dimensions of products vary widely, the median offers a more stable reference point, reflecting the middle of the distribution.

The Robustness of Mode: Echoes of Frequency

The mode is the echo of frequency – the value that occurs most frequently in a dataset. In quality control, the mode can reveal the most prevalent defect, the common machine setting, or the frequently occurring parameter.

Identifying the mode aids manufacturers in focusing on the most recurrent issues. For example, if monitoring defect types, the mode indicates the defect that requires immediate attention.

Peering Beyond the Surface: Inferential Statistics Unveiled

As we grasp the essence of central tendency, let’s venture into the realm of inferential statistics – a tool for peering beyond the surface of raw data, unraveling hidden truths, and guiding decision-making.

The Oracle of Sample: Drawing Inferences from the Few

Inferential statistics is like an oracle that draws insights from a limited few. Instead of analyzing an entire dataset, manufacturers use samples to make inferences about the larger population. This allows for efficient decision-making without the need to examine every individual product or process.

For instance, if testing the strength of materials, manufacturers can conclude the entire batch based on a representative sample, saving time and resources.

The Confidence of Intervals: Navigating the Sea of Uncertainty

Confidence intervals are like a safety net in the sea of uncertainty. In inferential statistics, they provide a range within which the true population parameter is likely to fall. If, for example, estimating the average production time, a 95% confidence interval indicates the range where the true average is likely to be found.

Understanding confidence intervals allows manufacturers to navigate uncertainty, providing a level of confidence in their inferences despite the inherent variability in manufacturing processes.

The Dance of Hypothesis: Challenging Assumptions

Hypothesis testing is the dance of challenging assumptions. It involves formulating a hypothesis about a population parameter, collecting data, and then assessing whether the observed results provide enough evidence to reject or accept the hypothesis.

In quality control, hypothesis testing allows manufacturers to challenge assumptions about their processes. For example, if aiming to improve production efficiency, a hypothesis test can determine whether a proposed change leads to a significant improvement.

Central Tendency in Action: Application in Quality Control

Now that we’ve grasped the essence of central tendency and inferential statistics, let’s witness how these concepts come to life in the dynamic world of quality control.

Quality Assessment with Averages: Mean as the North Star

Imagine the mean as the North Star guiding quality assessment. If measuring the weight of products, the mean weight provides a reference point for determining whether individual products deviate from the expected average.

Manufacturers can set quality standards based on the mean, ensuring that products align with the desired specifications. Deviations from the mean prompt further investigation, helping identify potential issues in the manufacturing process.

Stability Checks with Medians: A Stable Middle Path

The stability of the manufacturing process can be assessed using the median as a stable middle path. If monitoring production times, the median offers a robust measure of central tendency that is less sensitive to outliers.

Checking the stability of the median over time helps manufacturers identify variations that may indicate underlying problems. It’s a valuable tool for maintaining consistency in manufacturing processes.

Addressing Frequent Issues with Mode: The Common Thread

The mode acts as a common thread, highlighting the most frequent issues in quality control. If monitoring defects, identifying the mode indicates the most common type of defect that needs immediate attention.

Addressing frequent issues highlighted by the mode allows manufacturers to prioritize improvements. It’s a targeted approach that focuses on resolving the most prevalent challenges within the manufacturing process.

The Art of Inference: Guiding Decision-Making in Quality Control

Let’s explore how inferential statistics becomes an art form, guiding decision-making in quality control and process improvement.

Efficient Decision-Making with Samples: The Oracle’s Whisper

Efficient decision-making is achieved through the oracle’s whisper of samples. If testing the tensile strength of materials, manufacturers can conclude the entire batch by analyzing a representative sample.

Sampling allows for timely decisions, ensuring that manufacturers can make informed choices without the need to assess every individual product or process. It’s a practical approach that balances precision with resource efficiency.

Navigating Uncertainty with Confidence Intervals: The Safety Net

Confidence intervals serve as a safety net in navigating uncertainty. If estimating the average defect rate, a confidence interval provides a range within which the true population parameter is likely to fall.

Manufacturers can make decisions with a level of confidence, acknowledging the inherent variability in manufacturing processes. Confidence intervals act as a guide, helping manufacturers navigate uncertainty and make informed choices.

Challenging Assumptions through Hypothesis Testing: The Dance of Discovery

Hypothesis testing is the dance of discovery, challenging assumptions in quality control. If proposing changes to improve efficiency, manufacturers can formulate hypotheses, collect data, and statistically assess whether the changes lead to significant improvements.

This process of challenging assumptions through hypothesis testing is a cornerstone of continuous improvement. It allows manufacturers to validate the effectiveness of proposed changes before implementing them on a larger scale.

Navigating the Seas: Key Takeaways

As we navigate the seas of central tendency and inferential statistics in quality control, let’s gather the key takeaways that will guide manufacturers on their journey toward excellence.

Central Tendency: Averages (mean, median, mode) provide reference points for quality assessment and stability checks.

Inferential Statistics: Sampling, confidence intervals, and hypothesis testing enable efficient decision-making and guide process improvements.

Efficient Decision-Making: Samples offer insights about the entire population without analyzing every individual unit.

Navigating Uncertainty: Confidence intervals provide a range within which the true population parameter is likely to fall.

Challenging Assumptions: Hypothesis testing allows manufacturers to assess the effectiveness of proposed changes before widespread implementation.

The Heartbeat of Improvement: Central Tendency and Inference in Harmony

In the grand symphony of quality control, central tendency and inferential statistics resonate as the heartbeat of improvement. Manufacturers, like skilled conductors, must harmonize these concepts to create a masterpiece of efficiency and excellence.

Central tendency provides the rhythm, guiding quality assessment, and stability checks. Inferential statistics add the melody, enabling efficient decision-making and guiding manufacturers in their continuous quest for improvement.